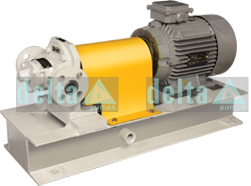

External Gear Pump ( Series DG )

An external gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications.

| (DGLP Series) (Low Pressure range) | (DGHP Series) (High Pressure range) | |

|---|---|---|

| Max. Capacity: | 1000 Ipm | 225 Ipm |

| Max Pressure: | 12 bar | 250 bar |

| Max.Viscosity: | 100000 cSt | 1000 cSt |

| material of Construction | ||

| Body: | Cast Iron/Carbon Steel/SS | Alluminium alloy /Cast Iron |

| Rotor: | Carbon Steel / SS | Carbon Steel |

Working Principle:

- External gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear.

- Each gear is supported by a shaft with bearings on both sides of the gear.

- As the gears come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the gear teeth as they rotate.

- Liquid travels around the interior of the casing in the pockets between the teeth and the casing -- it does not pass between the gears.

- Finally, the meshing of the gears forces liquid through the outlet port under pressure.

Salient Features

- Only two rotating parts matting externally having principle of gear within gear.

- Single gland construction reduces leakage to minimum.

- Gears are well supported with the help of 4 bearings.

- Self priming in nature.

Cost Implications:

- Very economical and costs fraction of the cost of gear, vane or screw pumps

- Power consumption is less than conventional pumps

Typical Applications:

- Transfer of liquid

- Booster application